Installation

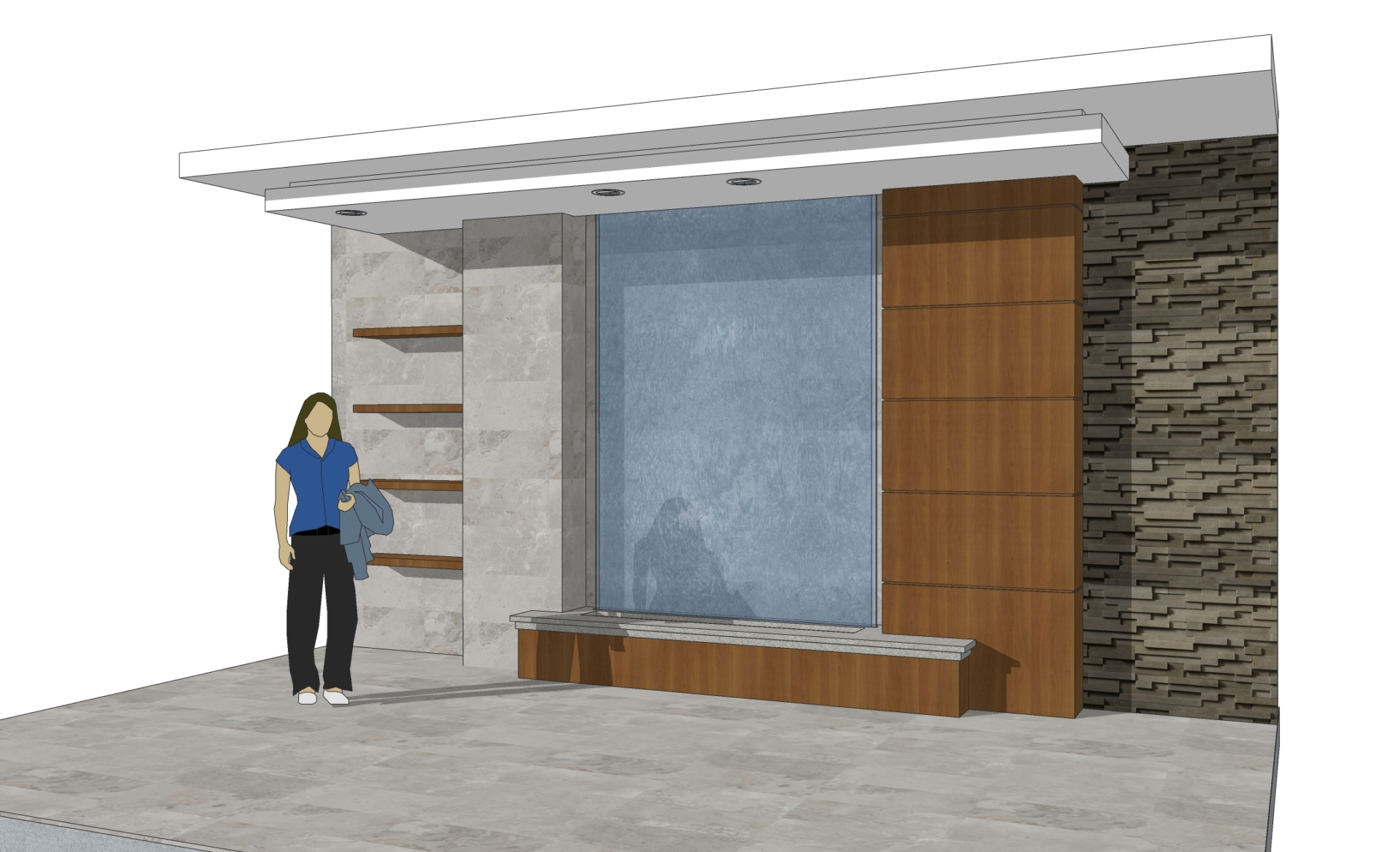

Superior Engineering: Reveal 7

the reason why there is no need to offer installation:

Water feature systems designed for installation without specialized skills.

Properly engineered ‘system’ products, by design, do not require specialized skills to be installed correctly. Origin Falls’ interior water walls are designed with the installer in mind and with an emphasis on simplicity utilizing standard construction practices every step of the way. We know that our systems are comprehensive to install and the proof is in the end result and the fact that we seldom receive questions from installers during installation. The overpriced ‘specialized’ installation services that others sell are simply a result of products that are ill-conceived, difficult to install and consequently difficult for the end user to maintain without the same specialized knowledge.Why purchase a product specifically designed for complexity that requires a buyer to pay a premium just to have it installed correctly? If that doesn’t seem quite right to you, well your not alone since it doesn’t make much sense to us either. Paying more for on-site installation by so-called ‘specialist’ may provide little more than a false sense of security and is completely unnecessary. Choose Origin Falls’ Reveal 7 Professional interior water walls instead and discover the cost savings and freedom to install your water feature anytime convenient to your construction schedule- no additional scheduling or coordination required.

Origin Falls offers superior engineered interior water walls free from specialized installation requirements. Our interior water walls are designed for installation by local contractors- the same professionals you already know and trust. Our indoor water feature systems are specifically designed to allow any contractor the ability to install with ease and confidence.

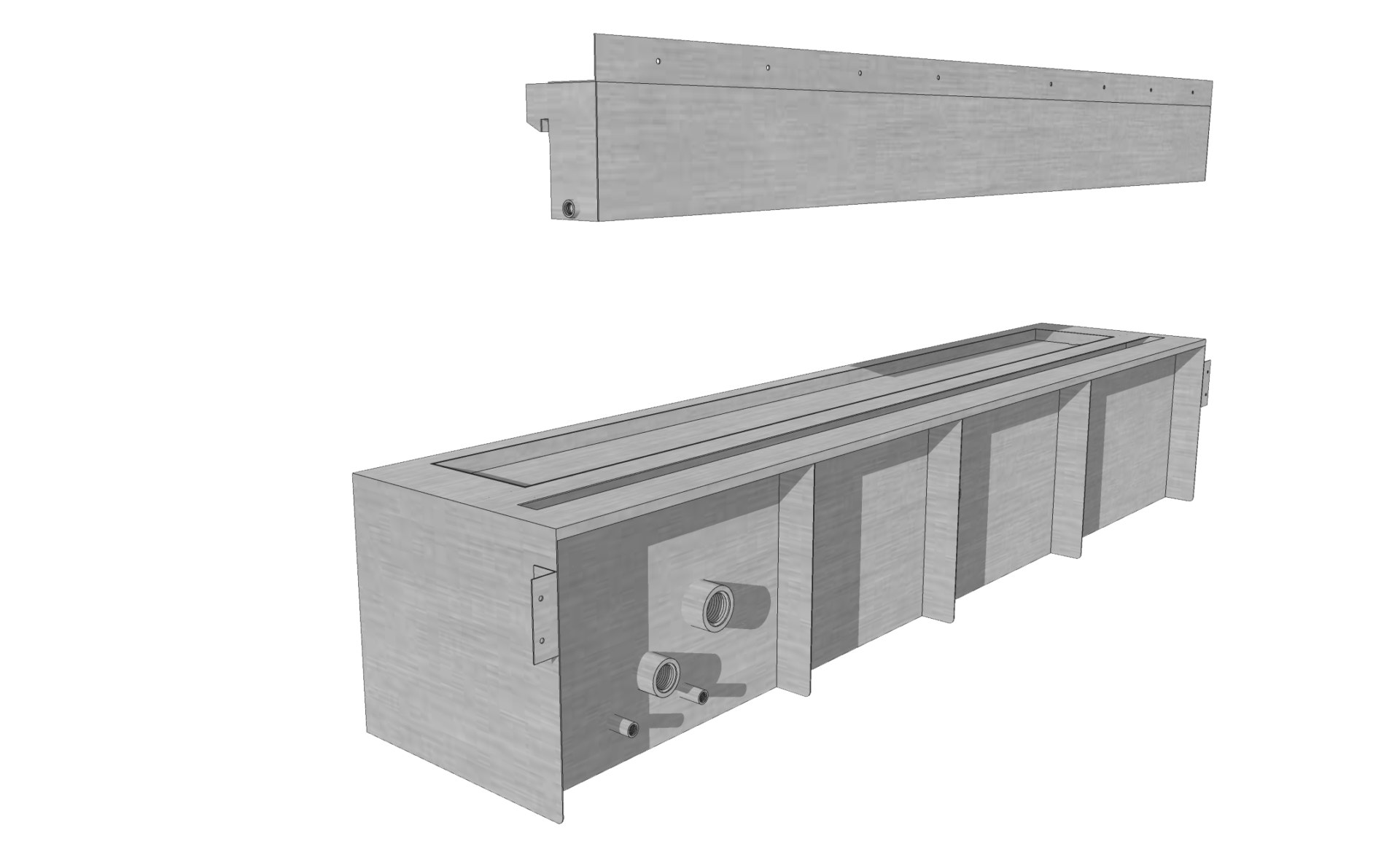

Fitting Group: Option #1- Back/Right

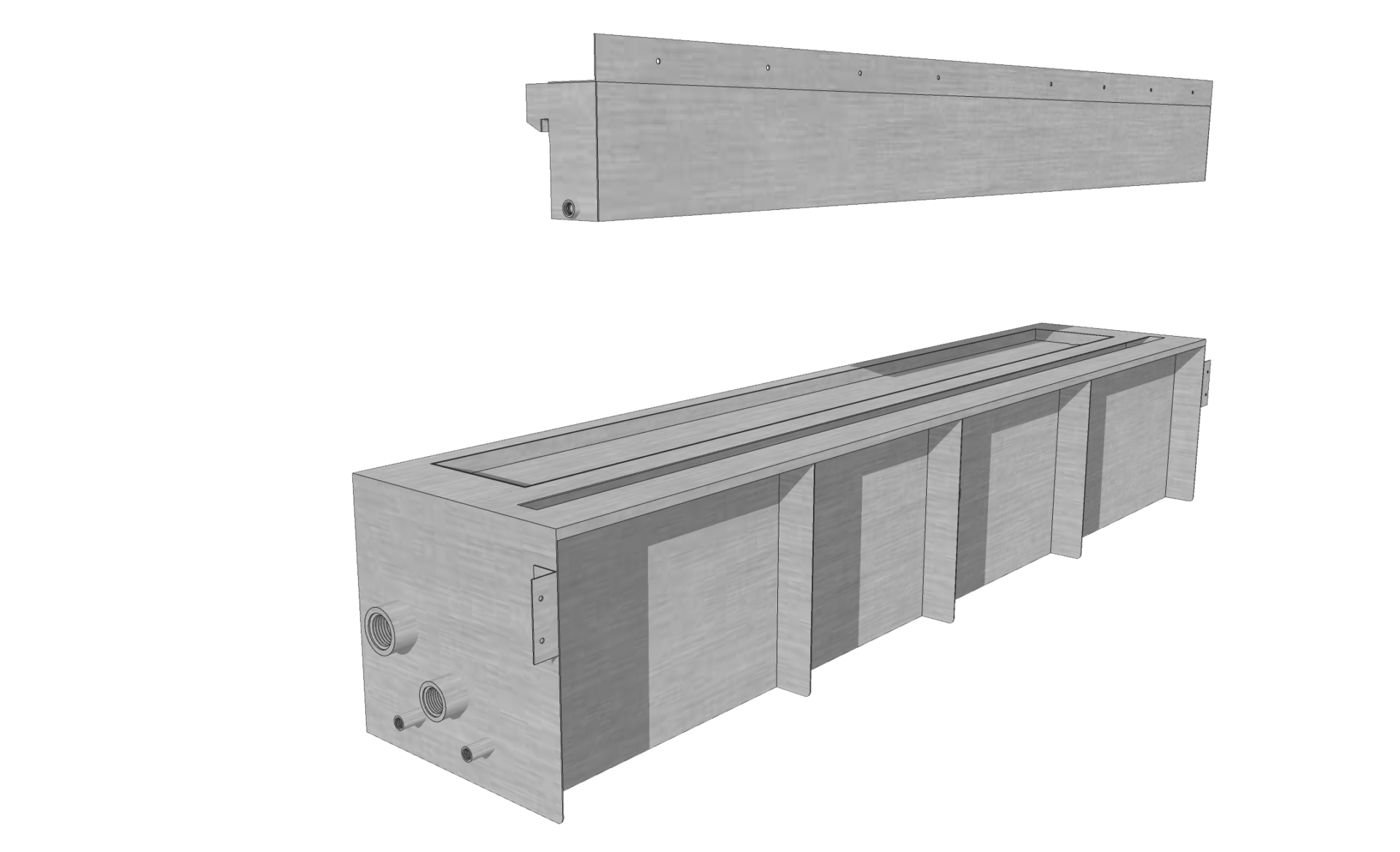

Fitting Group: Option #2- Back/Left

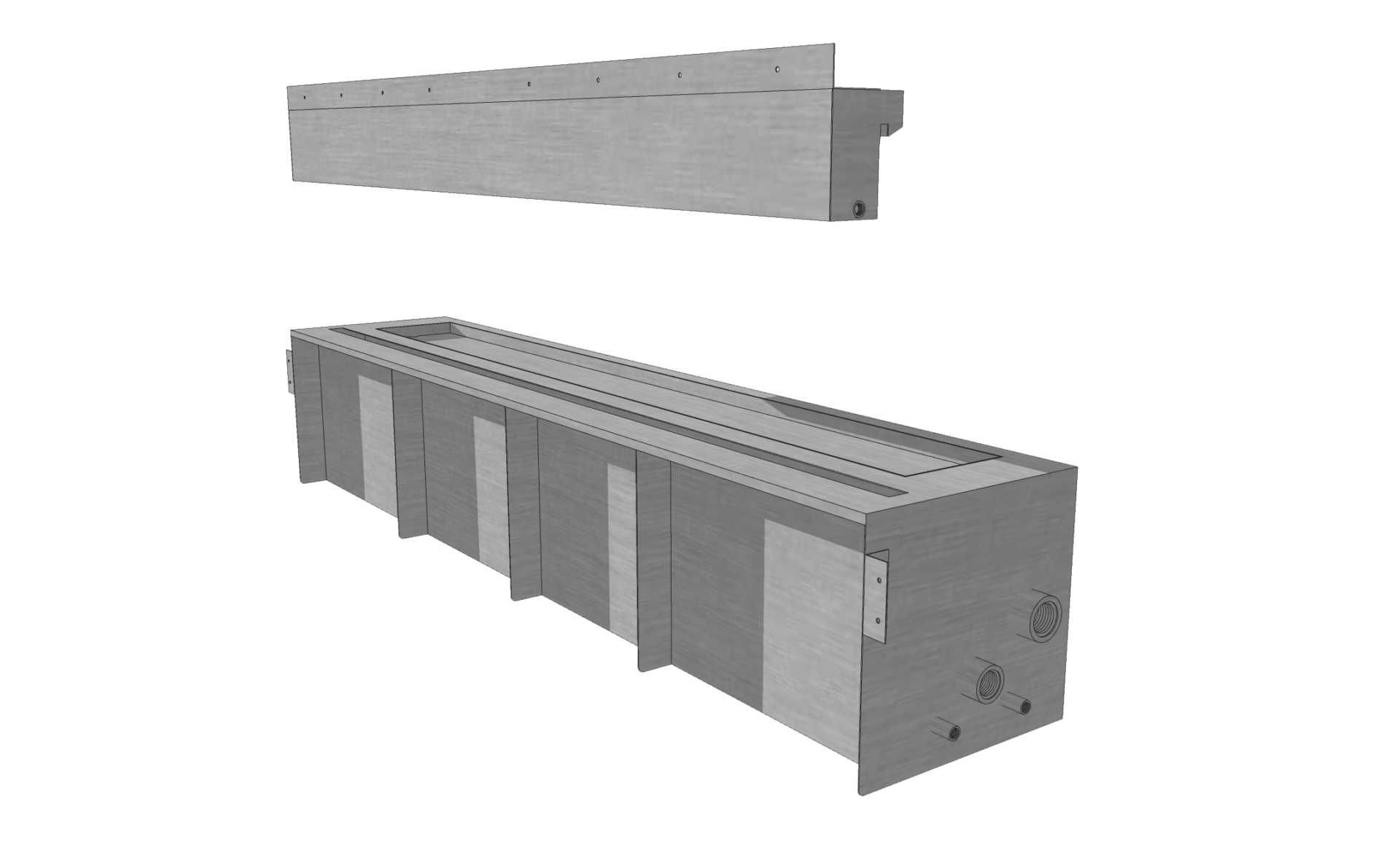

Fitting Group: Option #3- End/Right

Fitting Group: Option #4- End/Left

Our most durable system for high-load, high-height tempered glass surfaces. Fabricated from stainless steel and equipped with welded FNPT fittings installed as required for each individual water feature installation. The top surface of the lower basin features a linear grain finish. The access cover is reversible to provide a tray to contain river rock (river rock by others) and is removable for required service access. Lower basins are one-piece and designed with a continuous channel for multiple glass panels as required.

Sizes:

- Custom Widths from 40″ to 124″ standard.

- Overall water feature height is user defined and determined at time of ordering.

- Glass panel height dimension as required and determined at time of ordering.

System Loads:

- Lower basin: 25# / L.F.

- Upper basin:5# / L.F.

- Total (operating load): 80# / L.F.

- Total (operating load): 80# / L.F. + based on glass height

Floor Deflection Limits:

- All systems: L/480 LL+DL.

Note: installations should be planned for areas

where floor deflection is limited to L/480.

Warranty:

1 year parts and labor limited warranty.

2 year manufacturers warranty on all pumps.

Materials:

- Lower basin: stainless steel.

- Upper basin: stainless steel.

Installation Locations:

- Interior: yes

- Exterior: yes

Mechanical:

- Automatic Fill: yes

- Drain Connection: yes

- Water Supply: 1/2″ cold water to reverse osmosis

- Electrical: GFCI circuit required

- Electrical specifications and requirements will vary based on overall width and height of waterfall.

- Connections to building water supply and sanitary are optional but highly recommended to minimize required maintenance and to provide overflow protection.

Allowable Surfaces:

- Fully Tempered Glass: 12mm (1/2”) only- all (4) edges flat polished.

- Multiple glass panels may be required for systems over 76″ wide.

- Multiple panel design: butt-glazed to custom spacing.

- System designed for standard 12mm (1/2″) thick float glass only.

- Single glass panel width dimension limited to 72″

- Textured glass is not recommended

Reveal 7 Pro Glass

Standard components

Every order includes all the essential components to install professional interior water walls. We also offer optional equipment depending on the installation. Here’s what’s included:

The stainless steel upper basin is equipped with a welded mounting flange, welded fittings and integral manifold for precise and even water distribution along the entire water feature glass surface. A built-in channel designed for 12mm (1/2″) standard float glass assures positive placement of the glass during installation. A standard quick-connect drain connection allows water within the upper basin to drain back to the lower basin when the water feature is not in use. The overall length of the upper basin component is determined by the length of the lower basin and is generally 6″ less- refer to specifications above.

All stainless steel water feature systems are fabricated with a removable access cover / tray, finished on both sides and designed to be convertible for different applications. The flush surface cover configuration can be use as an exposed finish or may be inverted to provide a removable tray to contain river rock or other finish materials. The standard stainless steel tray / cover is required for the operation of the waterfall.

Submittals are expertly prepared by our experienced staff. We fully understand all construction types and use groups and as a result our water feature submittals and indoor water feature systems are accurately produced to integrate within the context of your building and construction detail requirements. Shop drawings for how to build an indoor waterfall typically include plans, sections, elevations and large scale details coordinated within the building design including relevant adjacency (detailed shop drawings only). Our component drawings are included at no additional cost and are standard for every order. Detailed shop drawings are included as an option for all orders and pricing is based on the level of detailed required for each individual installation.

Our quality asynchronous submersible pumps are virtually silent, energy efficient and are designed to operate 24/7. Pumps sizing is determined by the overall width and height of the water feature. Multiple pumps are typically required for indoor waterfall systems over 76″ in length.

Additional hardware included: 3/8″ PEX tubing, and structural silicone.

Origin Falls was first to introduce an ozone based water purification system designed specifically for purifying water in our water walls and we continue to innovate with our o3 Zone Pure Water Systems™ for indoor waterfall systems. Designed into each of our indoor waterfalls are the most advance ozone sanitation systems. It is a well known fact that ozone effectively kills legionella. Since 1999 Origin Falls has been collaborating with a leading ozone system manufacturer to incorporate the latest ozone technology into all of our products. We have developed a system using proprietary technology that is completely reliable and low maintenance. Our ozone systems provide sanitation and disinfection in multiple applications, with no negative impact on the environment. These benefits accrue across all our core products, leading to lower costs, better health, protection from litigation, fewer negative outcomes, and knowing for sure that your sanitation requirements are met.

Every Origin Falls water feature systems include as standard equipment a simple to maintain reverse osmosis water purification system designed specifically for our Reveal 7 Professional indoor / outdoor water feature systems.

Our built-in drain pump system includes a small auxiliary pump that is internally connected to the lower basin overflow drain to provide for simple mechanical removal of the water feature water for the purposes of maintenance and routine cleaning. This pump can also be programmed to automatically remove a small quantity of water from the reservoir and replenish it with fresh water at intervals determined by the user.

Our work doesn’t stop at the loading dock. After the many hours we have spent building your indoor waterfall, we want it to arrive in perfect condition. We carefully crate each indoor waterfall kits in our facility and supervise the loading.

Friendly and knowledgeable support is available prior to purchase and for the life of your waterfall. Our excellent support is one of the many reasons for our success. Find out how to build an indoor waterfall and more about our indoor waterfall kits.

Interior water walls: configurations

Reveal 7 Pro™ Glass design options

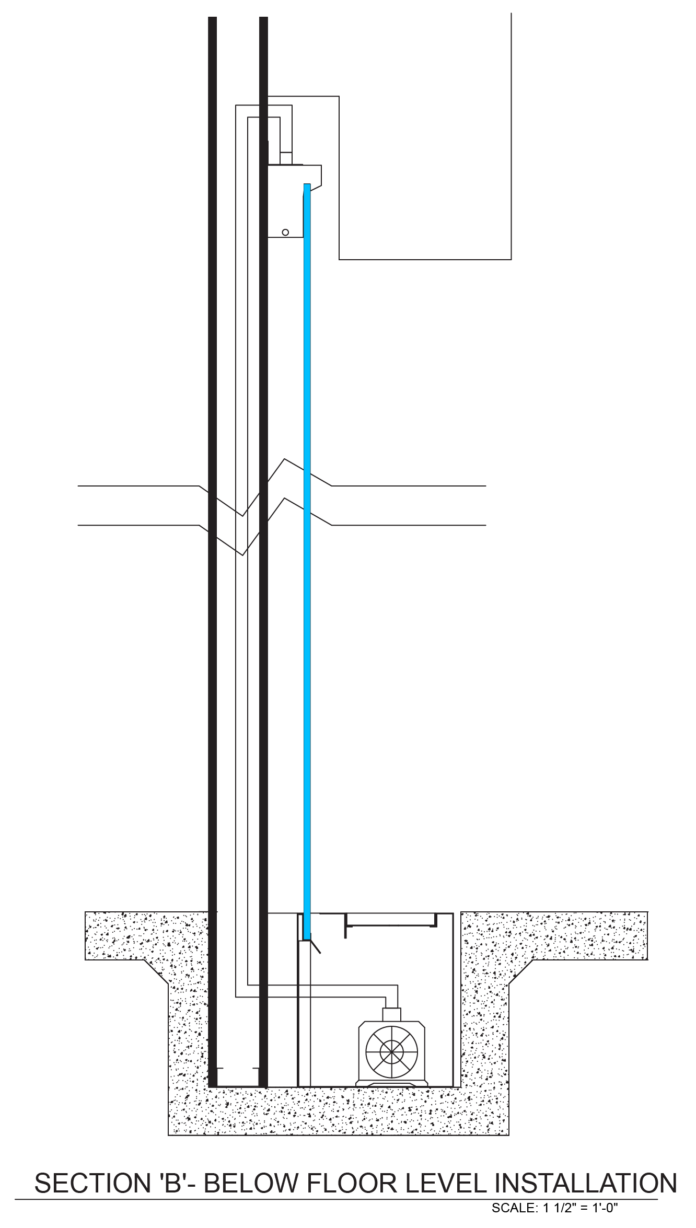

Origin falls routinely assist architects and designers during the schematic and design development phases to accurately prepare their construction documents for basic mechanical and functional installation requirements for our indoor water features. Competent indoor waterfall designs and detailing is critical to the success of any significant indoor waterfall project. Our level of experience and attention to detail is a testament to our dedication to the art of our contemporary water features. Included below are some typical sections to assist you in better understanding how our water feature systems can be implemented into your project.

- 3 5/8″ metal (3 1/2″ wood) stud frame minimum dimension (back supporting wall).

- Wet wall substrate as specified on component drawings.

- Adjacent finishes / context as required.

- Interior or exterior installations.

- Fittings do not exit bottom surface of lower basin.

- 3 5/8″ metal (3 1/2″ wood) stud frame minimum dimension (back supporting wall).

- Wet wall substrate as specified on component drawings.

- Adjacent finishes / context as required.

- Interior or exterior installations.

- Fittings do not exit bottom surface of lower basin.

- 3 5/8″ metal (3 1/2″ wood) stud frame minimum dimension (back supporting wall).

- Wet wall substrate as specified on component drawings.

- Adjacent finishes / context as required.

- Interior or exterior installations.

- Fittings do not exit bottom surface of lower basin.